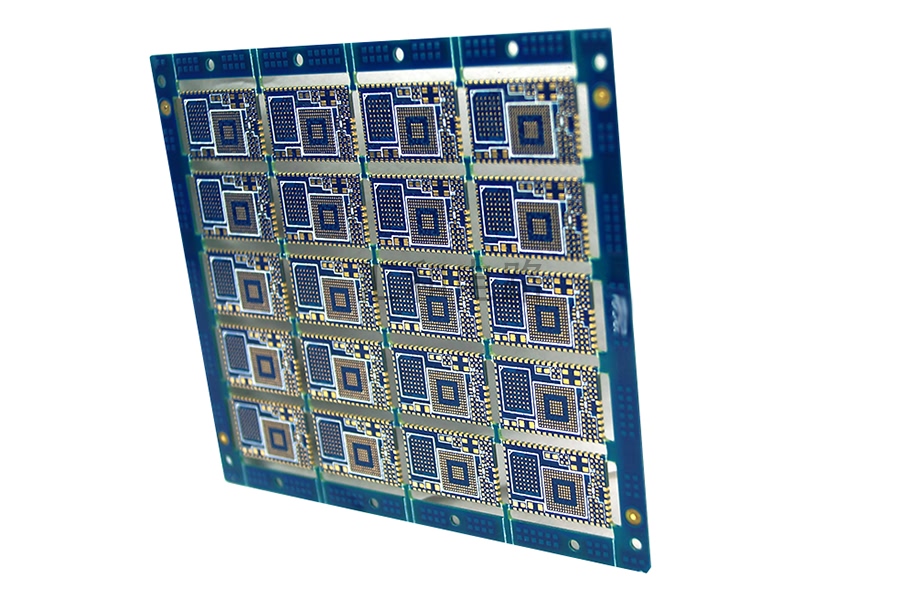

4 Layer ENIG FR4 Half Hole PCB

Ochiritsira Metallized Half-Hole PCB Fabrication Njira

Kubowola -- Chemical Copper -- Full Plate Copper -- Image Transfer -- Graphics Electroplating -- Defilm -- Etching -- Stretch Soldering -- Half Hole Surface Coating (Yopangidwa Nthawi Imodzi ndi Mbiri).

Bowo lazitsulo lazitsulo limadulidwa pakati pambuyo popanga dzenje lozungulira.N'zosavuta kuoneka chodabwitsa cha zotsalira mkuwa waya ndi mkuwa chikopa warping mu dzenje theka, zomwe zimakhudza ntchito ya dzenje theka ndi kumabweretsa kuchepa kwa ntchito mankhwala ndi zokolola.Pofuna kuthana ndi zolakwika pamwambazi, izo zidzachitika motsatira ndondomeko masitepe a metallized theka-orifice PCB:

1. Processing theka dzenje pawiri V mtundu mpeni.

2. Pakubowola kwachiwiri, dzenje lowongolera limawonjezeredwa pamphepete mwa dzenje, khungu lamkuwa limachotsedwa pasadakhale, ndipo burr imachepetsedwa.Ma grooves amagwiritsidwa ntchito pobowola kuti apititse patsogolo liwiro la kugwa.

3. Copper plating pa gawo lapansi, kotero kuti wosanjikiza mkuwa plating pa dzenje khoma la dzenje kuzungulira m'mphepete mwa mbale.

4. Dera lakunja limapangidwa ndi filimu yoponderezedwa, kuwonetseredwa ndi chitukuko cha gawo lapansi motsatizana, ndiyeno gawo lapansi limakutidwa ndi mkuwa ndi malata kawiri, kotero kuti wosanjikiza wamkuwa pa khoma la dzenje la dzenje lozungulira pamphepete mwa nyanja. mbale imakhuthala ndipo wosanjikiza wamkuwa umakutidwa ndi malata okhala ndi anti-corrosion effect;

5. Theka dzenje kupanga mbale m'mphepete kuzungulira dzenje kudula pakati kupanga theka dzenje;

6. Kuchotsa filimuyi kudzachotsa filimu yotsutsa-plating yomwe imakanizidwa panthawi yosindikizira filimu;

7. Mangani gawo laling'ono, ndipo chotsani chingwe chamkuwa chowonekera pakunja kwa gawo lapansi pambuyo pochotsa filimuyo; Kupukuta kwa malata Gawoli limasendedwa kuti malata achotsedwe pakhoma lopangidwa ndi theka-perforated ndi mkuwa wosanjikiza pa semi- khoma la perforated likuwonekera.

8. Mukatha kuumba, gwiritsani ntchito tepi yofiyira kumamatira mbale za unit pamodzi, ndi pamzere wa alkaline etching kuti muchotse ma burrs.

9. Pambuyo pazitsulo zamkuwa zachiwiri ndi tini tating'onoting'ono pa gawo lapansi, dzenje lozungulira pamphepete mwa mbaleyo limadulidwa pakati kuti likhale theka la dzenje.Chifukwa mkuwa wosanjikiza wa dzenje khoma yokutidwa ndi malata wosanjikiza, ndi mkuwa wosanjikiza dzenje chikugwirizana kwathunthu ndi mkuwa wosanjikiza wa kunja wosanjikiza gawo lapansi, ndi kumanga mphamvu yaikulu, wosanjikiza mkuwa pa dzenje. khoma akhoza bwino kupewedwa pamene kudula, monga kukoka kapena chodabwitsa cha mkuwa warping;

10. Akamaliza theka-dzenje kupanga ndiyeno kuchotsa filimuyo, ndiyeno etch, mkuwa pamwamba makutidwe ndi okosijeni sizidzachitika, mogwira kupewa kuchitika kwa zotsalira zamkuwa ndipo ngakhale yochepa dera chodabwitsa, kusintha zokolola za metallized theka-dzenje PCB. .

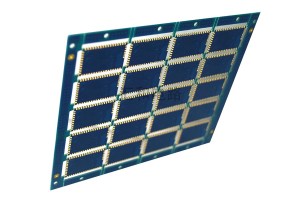

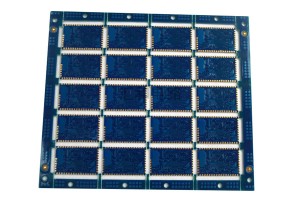

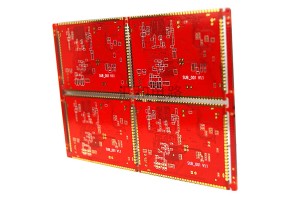

Chiwonetsero cha Zida

PCB Automatic Plating Line

Chithunzi cha PCB PTH

PCB LDI

PCB CCD Exposure Machine

Chiwonetsero cha Fakitale

PCB Manufacturing Base

Admin Receptionist

Chipinda Chokumana