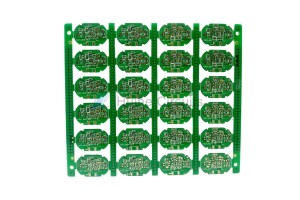

10 Layer ENIG FR4 Kudzera mu Pad PCB

Kudzera mu Pad PCB

Mu mapangidwe a PCB, bowo lodutsa ndi spacer yokhala ndi dzenje laling'ono losindikizidwa mu bolodi losindikizidwa kuti lilumikize njanji zamkuwa pagawo lililonse la bolodi.Pali mtundu wina wa dzenje lotchedwa microhole, lomwe limakhala ndi bowo lowoneka bwino pamalo amodzi aPCB ya multilayer yapamwamba kwambirikapena dzenje losaoneka lokwiriridwa pamtunda uliwonse.Kuyamba ndi kugwiritsa ntchito kwakukulu kwa pini zolimba kwambiri, komanso kufunikira kwa PCBS yaying'ono, zabweretsa zovuta zatsopano.Chifukwa chake, njira yabwino yothetsera vutoli ndikugwiritsa ntchito ukadaulo waposachedwa kwambiri koma wotchuka wa PCB wotchedwa "Via in Pad".

M'mapangidwe apano a PCB, kugwiritsa ntchito mwachangu kudzera pa pad kumafunika chifukwa cha kuchepa kwa magawo a mapazi komanso kuchepetsedwa kwa ma coefficients a mawonekedwe a PCB.Chofunika kwambiri, chimathandizira kuwongolera ma siginecha m'malo ochepa a mawonekedwe a PCB momwe ndingathere ndipo, nthawi zambiri, amapewa ngakhale kudutsa gawo lomwe chipangizocho chili nacho.

Ma pass-through pads ndi othandiza kwambiri pamapangidwe othamanga kwambiri chifukwa amachepetsa kutalika kwa njanji motero amawongolera.Muyenera kuyang'ana kuti muwone ngati PCB wopanga ali ndi zida zokwanira kupanga bolodi lanu, chifukwa izi zitha kuwononga ndalama zambiri.Komabe, ngati simungathe kuyika pa gasket, ikani mwachindunji ndikugwiritsa ntchito zingapo kuti muchepetse inductance.

Kuphatikiza apo, pad pass pad ingagwiritsidwenso ntchito ngati pali malo osakwanira, monga ma micro-BGA design, omwe sangagwiritse ntchito njira yachikhalidwe ya fan-out.Palibe kukayika kuti zolakwika za kupyola mu dzenje mu kuwotcherera chimbale ndi ang'onoang'ono, chifukwa ntchito mu kuwotcherera chimbale, zotsatira pa mtengo ndi lalikulu.Kuvuta kwa njira zopangira komanso mtengo wazinthu zoyambira ndi zinthu ziwiri zazikulu zomwe zimakhudza mtengo wopangira ma conductive filler.Choyamba, Via in Pad ndi gawo lowonjezera pakupanga kwa PCB.Komabe, kuchuluka kwa zigawo kumachepetsa, momwemonso ndalama zowonjezera zomwe zimagwirizanitsidwa ndi ukadaulo wa Via mu Pad.

Ubwino Wa Via In Pad PCB

Kudzera mu PAD ma PCB ali ndi zabwino zambiri.Choyamba, zimathandizira kachulukidwe kachulukidwe, kugwiritsa ntchito mapaketi otalikirana bwino, komanso kuchepetsedwa kwa inductance.Kuphatikiza apo, podutsa mu pad, kudzera imayikidwa mwachindunji pansi pa zolumikizira za chipangizocho, chomwe chimatha kukwaniritsa kachulukidwe kakang'ono komanso kanjira kopambana.Chifukwa chake imatha kupulumutsa mipata yambiri ya PCB ndi pad ya PCB wopanga.

Poyerekeza ndi vias akhungu ndi vias m'manda, kudzera pa pad ali ubwino zotsatirazi:

Oyenera tsatanetsatane mtunda BGA;

Sinthani kachulukidwe ka PCB, sungani malo;

Kuonjezera kutentha kutentha;

A lathyathyathya ndi coplanar ndi chigawo Chalk amaperekedwa;

Chifukwa palibe chotsatira cha fupa la galu, inductance ndi yotsika;

Wonjezerani mphamvu yamagetsi ya doko la chiteshi;

Kudzera mu Pad Kufunsira kwa SMD

1. Ikani dzenjelo ndi utomoni ndikulipaka ndi mkuwa

Yogwirizana ndi yaing'ono BGA VIA mu Pad;Choyamba, njirayi imaphatikizapo kudzaza mabowo ndi zinthu zochititsa chidwi kapena zopanda conductive, ndikuyika mabowowo pamwamba kuti apereke malo osalala kuti azitha kuwotcherera.

Bowo lodutsa limagwiritsidwa ntchito pamapangidwe a pad kuti akhazikitse zigawo pa dzenje lachiphaso kapena kukulitsa zolumikizira za solder ku kulumikizana kwa dzenje.

2. Ma microholes ndi mabowo amaikidwa pa pad

Ma Microholes ndi mabowo a IPC okhala ndi mainchesi osakwana 0.15mm.Zitha kukhala dzenje (zokhudzana ndi chiŵerengero cha mawonekedwe), komabe, kawirikawiri microhole imatengedwa ngati dzenje lakhungu pakati pa zigawo ziwiri;Ma microholes ambiri amabowoledwa ndi ma lasers, koma ena opanga ma PCB akubowolanso ndi timabowo ta makina, omwe amachedwa koma odulidwa mokongola komanso mwaukhondo;The Microvia Cooper Fill process ndi electrochemical deposition process for multilayer PCB process process, also known as Capped VIas;Ngakhale kuti ndondomekoyi ndi yovuta, ikhoza kupangidwa kukhala HDI PCBS kuti opanga PCB ambiri adzadzazidwa ndi mkuwa wa microporous.

3. Tsekani dzenje ndi wosanjikiza kuwotcherera kukana

Ndi yaulere komanso yogwirizana ndi ma solder SMD pads;Njira yowotcherera yokhazikika ya LPI siyingapange kudzaza dzenje popanda chiwopsezo chamkuwa wopanda kanthu mubowo.Nthawi zambiri, itha kugwiritsidwa ntchito pambuyo pa kusindikiza kwachiwiri kwa chophimba poyika UV kapena kutentha kwa epoxy solder kukana m'mabowo kuti atseke;Imatchedwa kudzera mu blockage.Kupyolera-bowo plugging ndiko kutsekereza kwa mabowo ndi zinthu zotsutsa kuti mpweya usatayike poyesa mbale, kapena kuteteza mabwalo amfupi a zinthu pafupi ndi pamwamba pa mbale.

-300x225.png)